Water-supply systems

ENGINEERED FOR EXCELLENCE

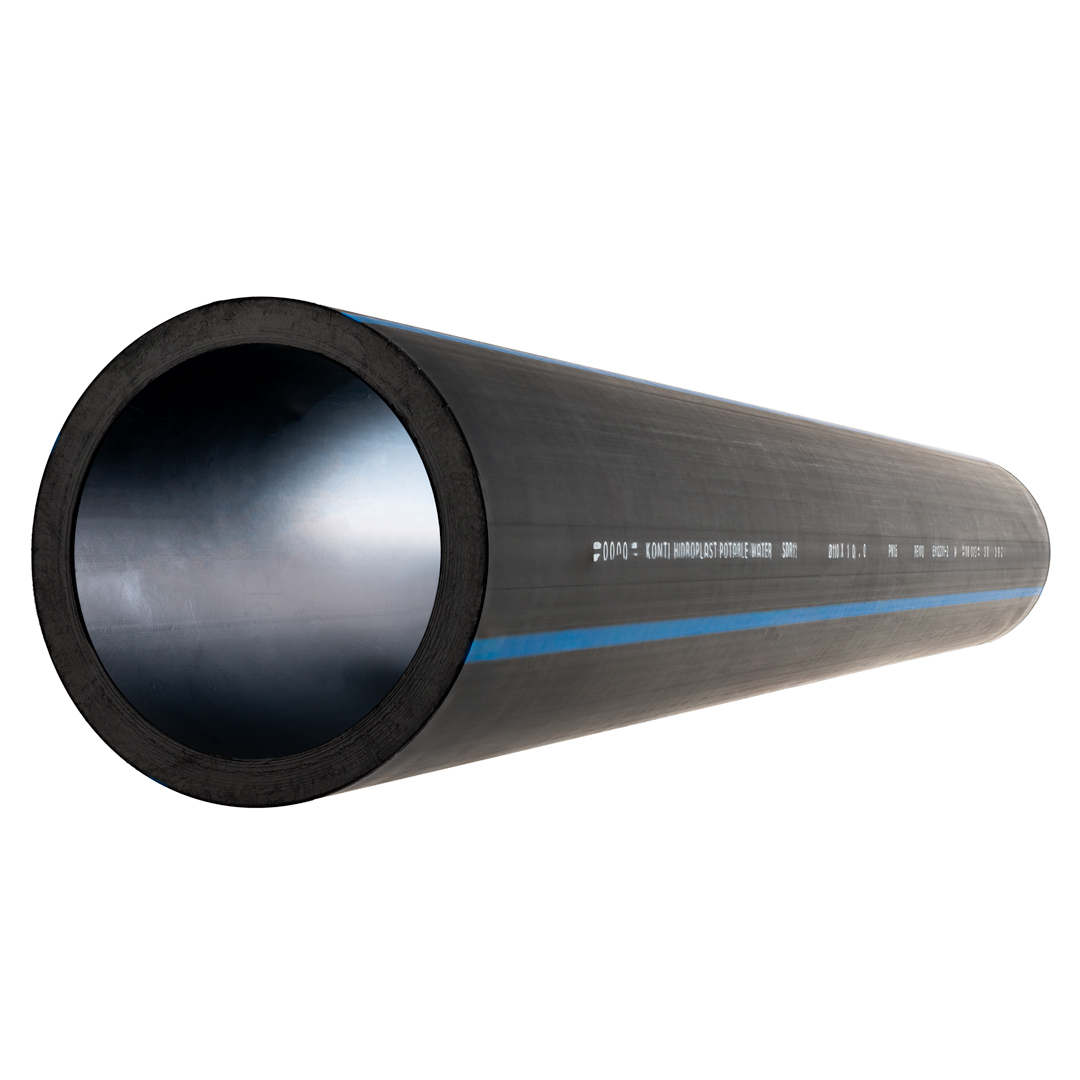

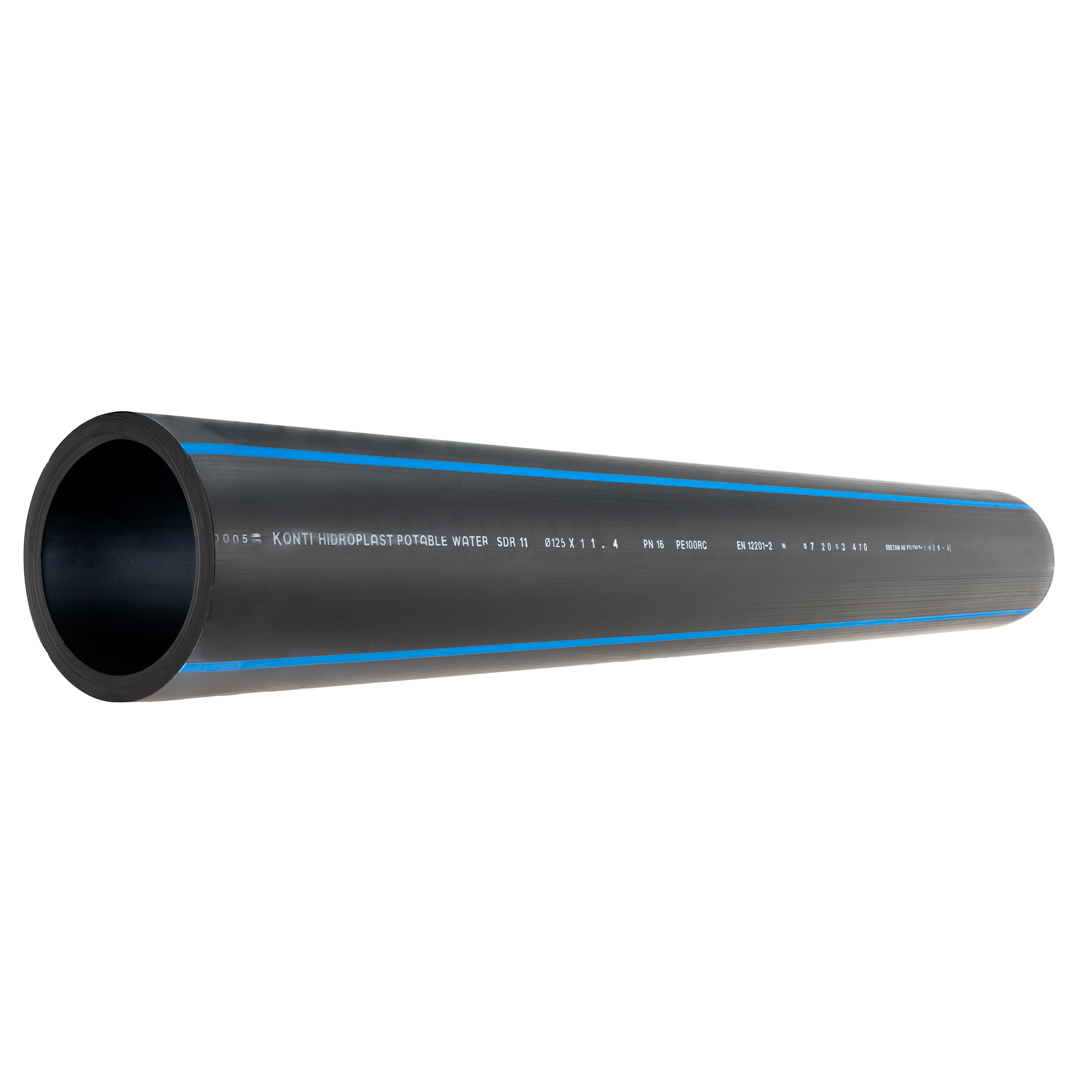

The pipes’ color is black with an inner white layer and coextruded blue lines, or blue with an inner white layer.

The range of diameters is from DN 16mm to DN 630mm, and the pressures are from PN 6 to PN 32 bar.

Pipes of the DN-16-110mm range are easily bended, so they can be wound in coils of different lengths, and the requirements for fittings and the time for installation can be reduced. Pipes of range 125-800mm are produced in straight pipes of 6 or 12m.

General properties of polyethylene pipes:

- Low specific weight

- Flexibility

- Good chemical resistance

- Excellent welding options

- Smooth internal surface resistant to deposits

- Suitable for drinking water

- Long lifespan (more than 50 years)

- 100% recycling possibilityApplication:

- Water-supply systems

- Gas Transport

- Sewerage systems

- Irrigation systems

- Protection of optical cables

Polyethylene water-supply pipes are made of high density polyethylene HDPE – PE 80, and are intended for transport of drinking water, food liquids and other liquids.

Standards:

- ЕН 12201-2

- Deign stress: σ=6.3Мпа

- MRS: 8

- Factor of safety: C=1.25

- Color: black with blue coextruded lines or light blue

Characteristics:

- Operating Temperature: -20°C to +60°C (ideal for cold and moderate climates).

- Can handle slight soil or ground movements without cracking.

- Designed for a service life of 50+ years under normal operating conditions.

- Excellent resistance to most chemicals, including acids, bases, salts, and organic compounds.

- Moderate resistance to UV degradation.

- Typically joined using butt fusion or electrofusion welding, creating leak-proof and durable joints.

- Smooth internal surfaces provide low friction losses, improving flow efficiency.

- Fully recyclable. Lower carbon footprint compared to traditional metal pipes.

PE 80 pipes are a reliable, cost-effective choice for medium-pressure applications. They provide good performance in water and gas distribution, agricultural irrigation, and industrial processes. For higher pressures, temperatures, or more demanding applications, PE 100 pipes may be more suitable.

Polyethylene water pipes are third generation PE of high density HDPE – PE 100, and are intended for transport of drinking water, food-liquids and other liquids. Wide range of application such as: water supply, gas distribution, irrigation, industrial processes, and sewer systems.

Standards:

- ЕН 12201-2

- Deign stress:: σ=8.0 Мпа

- MRS: 10

- Factor of safety: C=1.25

- Color: black with blue coextruded lines or blue

Characteristics:

- PE 100 material has an MRS of 10 MPa at 20°C over a lifespan of 100 years.

- Designed for high-pressure applications, with pressure ratings up to PN 32 (depending on the SDR).

- Operating temperature: -40°C to +60°C. Suitable for low-temperature conditions without risk of cracking.

- Highly flexible, making it suitable for uneven terrains, seismic zones, and trenchless installations.

- Service life of 50+ years, even under high-pressure conditions.

- Excellent resistance to a broad range of chemicals, including acids, alkalis, salts, and organic solvents.

- UV-stabilized grades (black color) of PE 100 have very good resistance on exposure to sunlight.

- Uses butt fusion or electrofusion welding, ensuring strong, leak-proof, and durable joints.

- Smooth internal surfaces provide low friction losses, improving flow efficiency.

- Fully recyclable and environmentally friendly. Lower carbon footprint compared to metal pipes.

PE 100 pipes are the premium choice for high-performance applications, providing unmatched durability, flexibility, and pressure resistance. Their ability to withstand high pressures and adverse environmental conditions makes them ideal for infrastructure projects, industrial systems, and critical utility services.

PE 100 RC (Resistance to Crack) pipes are a specialized variant of standard PE 100 pipes, designed for even greater resistance to slow crack growth and environmental stress cracking. These pipes are particularly suited for trenchless installations, demanding conditions, and long-term reliability. Below are the main performance characteristics of PE 100 RC pipes.

TYPE 1: Pipes with full walls made of PE-100 RC. Single-layered pipes with full walls made of PE-100 RC as defined in ISO 4065.

TYPE 2: Pipes with dimensionally integrated protective layer made of PE-100 RC. Double-layered pipes with dimensionally integrated protective layers consist of PE-100 or PE-100 RC and have an inner coextruded protective layer made of PE-100 RC. Triple-layered pipes with dimensionally integrated protective layers consist of PE 100 or PE 100-RC and have an inner and outer coextruded protective layer made of PE-100 RC. The coextruded layers are mutually and inseparably connected with special technology connecting the layers. Made of PE-100 RC, the inner layer is integrated as a functional layer within the wall structure.

TYPE 3: Pipes with dimensions according to ISO 4065 with dimensionally added outer protective layer made of PP. The pipes with dimensions as specified in ISO 4065 with outer protective layer consist of a basic pipe made of PE-100 RC/PE 100, single-layered or double-layered pipe and protective layer made of polypropylene. The minimal thickness of the protective layer is 0.8mm.

- Material: High quality PE 100-RC material and PE 100

- Standards: ЕN 12201-2 and PAS 1075

- Project elongation: σ=8.0Mpa

- Factor of safety: C=1.25

- Color: Black with yellow or orange lines, or entirely orange

- Service life of 100+ years under normal operating conditions, with added safety in environments prone to stress cracking.

- Fully recyclable and environmentally friendly.

PE fittings

Fitting Stub Ends (Welding Collars)

Fitting Stub Ends (Welding Collars)

Fitting – Concentric Reducer

Fitting – Concentric Reducer

Fitting – End Cup

Fitting – End Cup

Fitting – Tee Outlet Without Reinforcement

Fitting – Tee Outlet Without Reinforcement

Fitting – Tee Outlet Reducer

Fitting – Tee Outlet Reducer

Fitting – Tee Outlet

Fitting – Tee Outlet

Electrofusion Adapter Socket Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Socket Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 45° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 45° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 90° Integrated Welding Module Male Thread Out Of Brass

Electrofusion Adapter Elbow 90° Integrated Welding Module Male Thread Out Of Brass

Tapping Saddle With Electrofusion Sealing Cap Integrated Welding Module

Tapping Saddle With Electrofusion Sealing Cap Integrated Welding Module

Universal Tapping Valve With Thread Insert Out Of Brass Integrated Welding Module

Universal Tapping Valve With Thread Insert Out Of Brass Integrated Welding Module

Plastic Tapping Valve With Integrated Cutter Integrated Welding Module

Plastic Tapping Valve With Integrated Cutter Integrated Welding Module